Need automated storage shelves?

Contact us now for a free consultation and quote.

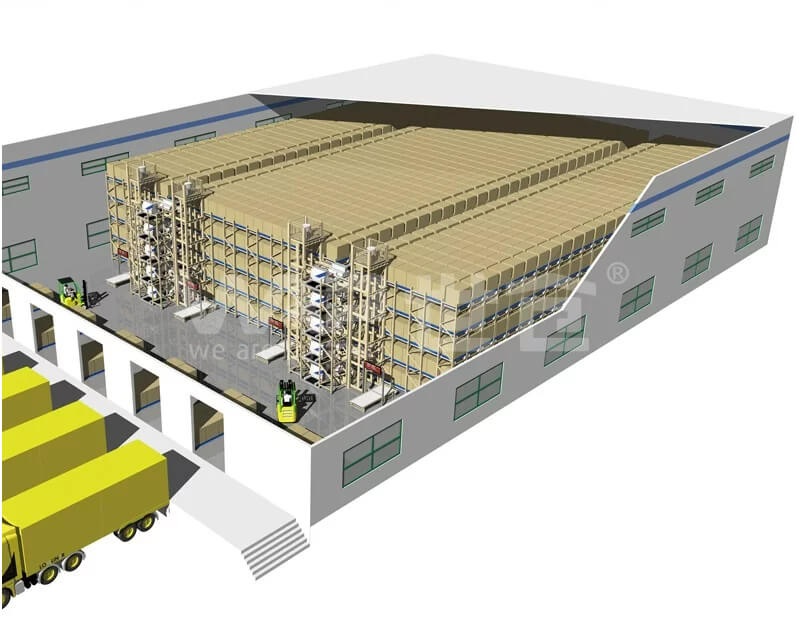

Shuttle Crane System

The Shuttle Crane System includes equipment such as shuttles, pallet racks, elevators, conveyors and remote controls. Shuttle Crane System is a fully automated storage solution for industrial warehouses, cold storage…

Robot system automatically picks up goods

Fast – sensitive remote control

Automatically move the row to the control direction

3D DESIGN OF Shuttle Crane System

Large-scale warehouse system

Applying shelves of Shuttle Crane System to store and transport goods

Is the Shuttle Crane System used?

The Shuttle Crane System is a combination of high-storage selective racks and automated picking robots. Accurate fast.

Industrial production

Cold storage with large area

Production storage supplies

Chemical factory, garment, electronics, supplies…

E-Commerce Warehouse

Finished goods warehouse

Specifications

– Maximum weight: 1500kgs/pallet

– Running speed without pallet: 0.7 – 1.2 m/s

– Running speed with pallet: 0.6 – 1.0 m/s

– Supported power source: Lithium battery

– Rated voltage: 26V

– Working time: More than 8 hours

– Range of radio remote controller: Max – 10m

– Custom request: Available

– Long service life, can be charged more than 1200 times

– Relatively light weight and weight

– Friendly, environmental protection

Operation Video of Shuttle Crane System

We describe the video in virtual digital, helping you visualize the warehouse operation in the most realistic way

our video solutionsHow the Shuttle Crane System Rack picks up goods

Import

First in, first out (FIFO) control is ensured by storing from the front of the Shuttle Crane System and taking out from the opposite side. The same SKU is stored in each lane. (model system)

First in first out (Last in, first out)

The Shuttle Crane System is installed against the wall, storage and removal is done from the opposite side of the wall. Products with the same SKU and same lot are placed in the same lane.

Applicable models of Shuttle Crane System

IMPLEMENTED PROJECTS

Production process

Purchase consultation process

Stores nationwide – Long An factory

Viet Pos Rack has offices in Ho Chi Minh, Can Tho, Dong Nai, Nha Trang, Da Nang, Hanoi and a factory in Long An.

Receive information and analyze customer warehouse storage model.

Drawing + quotation

Make layout drawings and estimate quotes for customers’ reference

Deployment + Acceptance

Construction, installation, acceptance and handover to customers.

Selection of automated shelves for warehouses

Please contact us immediately for a free consultation, shelf lines, warehouse operation solutions suitable for your model, in the most cost-effective and scientific way.

Leave messageOther warehouse shelves

Viet Pos Rack also manufactures and installs many other types of storage racks. Depending on the size of the warehouse and the size of the goods, we will advise you on the most suitable type of shelf, to maximize cost savings.

Tiếng Việt

Tiếng Việt 中文 (Chinese)

中文 (Chinese) 한국어

한국어