Today, industrial shelving and racking has evolved enormously thanks to the technological potential of robotics, artificial intelligence, and computer science. Each of them have contributed to building the transition bridge between manual and automated storage.The modern industrial shelf, in addition to storing things, also serves as a support to arrange products in order to later transport them. Industrial shelving is usually made up of load beams or shelf panels, support crossbars, row spacers and protectors. Contact us immediately at hotline: (+84) 796 700 777 for advice if you have a need to buy warehouse shelves, automatic shelves.

Why is it important to have industrial storage shelves?

– Through storage shelving and racking systems it’s possible to reduce the number of staff members in charge of storage as well as transport and delivery time.

Industrial storage classification

Manual storage systems

Overview of heavy duty warehouse shelves

Automated storage system

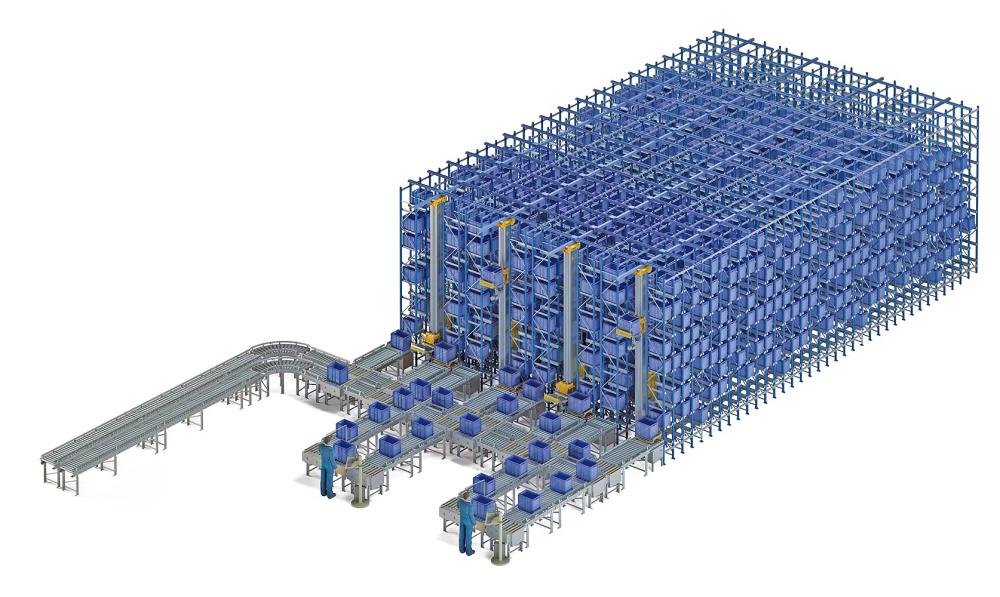

Automated storage systems are the other side to storage mechanics. Therefore, its structure is almost completely independent from human intervention. This type of racking represents an innovative system created to optimize storage as much as possible. It is achieved by cleverly manipulating the positioning and order of products, which also increases safety within the industrial environment.

Automated warehouse systems are used for pallets and for cartons, enabling maximum optimisation, not just of the space but also in terms of efficiency and work times.

ASRS solution – Automated cargo storage system

Professional shelf production process

Automatic stamping machine

Omega leg rolling system

Beam rolling system

Automatic welding process

Powder Coating

Careful packaging process

Typical customers

Tiếng Việt

Tiếng Việt 中文 (Chinese)

中文 (Chinese) 한국어

한국어